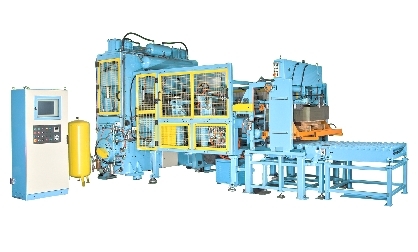

Automatic CNC Sheet Feeding Press B23E+B86B+B85A

Automatic CNC Sheet Feeding Press B23E+B86B+B85A

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

This CNC sheet feeding press equipped with three axis synchronized movement is suitable for tin or aluminum end stamping。 European servo motors, electronic cam control system and Japanese PLC control system are incorporated. Programmable integrated sheet take-over system can get precise sheet feeding。 Besides, a reliable industrial computer is introduced as a main control unit for data calculation, transmission and display。 Single crankshaft with double action makes the cutting bur stay at the inner side of the curl。 This can avoid the scratch on the end seaming panel while ends are piled up during transportation.

coming soon

coming soon

coming soon

Specifications

| MACHINE TYPE | S-B23BH, S-B86, S-B85 |

|---|---|

| Range of end dia. | 200D~603D |

| Number of tooling set | 2~7 sets (depend on end size and sheet size) |

| Capacity per min. | variable 140~200 strokes(100~150 strokes*) |

| Sheet Size range | (700~1067)W x (830*~1067)L mm |

| Capacity of press | 30/60 tons |

| Horse power required | |

| X1,Y1,Y2 axis | 2.1Kw, 5.9Kw, 4.1Kw |

| Main motor for press | 30 HP x 6P |

| End discharge conveyor | 1HP x 6P |

| Scrape discharge conveyor | 1/2 HP x 6P |

| Air compressor motor | 10Hp |

| Area of outer ram | 1350 x 300 mm |

| Area of inner ram | 1640 x 200 mm |

| Area of bolster | 1640 x 300 mm |

| Max. die height of outer ram | 380mm |

| Max. die height of inner ram | 510mm |

| Stroke of outer ram | 60mm |

| Stroke of inner ram | 80mm |

| Floor space overall height | 7782L x 4000W x 3155+/- 50H mm |

| Net weight (approx) | Kgs |

| *Capacity can be reduced to range 100~150 stroke per min. by changing the motor pulley *Min. sheet length depends on end size. |

|

Features

- Industrial Computer with human-machine interface (15” touchable screen) acts as a main control unit。

- Movement orbit generate and download automatically, easy for different end size parameters set up。

- With reliable European servo motors to reduce the inertia at high speed。

- Each axis movement can be manually checked。 Besides, created movement orbit is confirmed automatically to ensure if it is within the safety range on each axis。

- Equipped with sensors to detect if the clips certainly clip the sheet.

- Multiple safety control; for example,machine stop for low air pressure、lack of oil、jam at exit。Moreover,safety range detection on each axis is equipped。

- Equipped with air brake clutch, safe and reliable。

- Tooling with pillar die set can be easily pushed into via rollers buried on bolster.

- Pneumatic cylinders are equipped to lower scrap ejection system and inlet guide plate to easily access the toolings.

- End ejection is controlled by electronic cam adjustment to avoid double punch。

- Bushes on crankshaft are properly lubricated by an automatic grease pump。

- Four sets of air cushion cylinders located at upper side to balance the weight of rams and toolings.

- Suitable for straight or pre-scrolled tin /aluminum sheet。

Layout Dimension

coming soon