S-B10A-5 Automatic Ends Stacker And Counter

S-B10A-5 Automatic Ends Stacker And Counter

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

S-B10A-5 Automatic End Counter and Stacker is specially designed for small round end and is recommended to link with two sets of lining/drying machine S-B10A. Dried ends are guided by by two chutes to reach the top conveyor then enter collection channel. Ends enter counting station, a pair of separating knives and a sensor undertake counting and collecting task. Counted ends stay at hemisphere trough and then are pushed forward by a linear cylinder to reach the end of the said trough. Manually push is required to make ends enter a paper bag. Simple design and multiple safety devices, easy for maintenance and can size changeover.

coming soon

Specifications

| Machine Type | S-B10A-5 |

|---|---|

| Range of End Dia. | 200 - 404D |

| Capacity Per Min. | Up to 700 Ends/min. |

| Horse Power Required | 1/2HP x 1 , 1/4HP x 1 |

| Compressed Air Required | 3kg/cm2 x 10L/Min. |

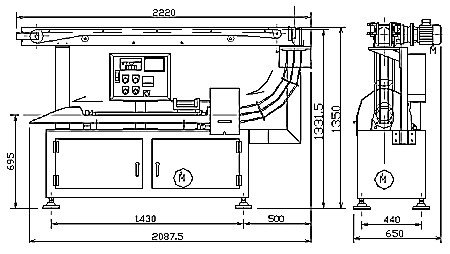

| Floor Space Overall Height | 2200 x 700 x 1550 mm |

| Net Weight | 650 kgs |

Features

- Easy for end size changeover and build for long life using.

- Precise ends counting, quick for resetting and adjusting.

- Multi-safety design for machine and personnel safety.

- Suitable for steel and aluminum ends counting and stacking.

- With PLC control system for ends auto stacking and counting operation.

- Equipped with inverter for variable speed control.

- Can be connected with two S-B10A drying ovens to save labor lost for normal food ends collection.

- For aerosol ends, two S-B10AP drying oven link to one S-B10A-5 is not recommended, S-B10A-6 is recommended for this purpose.

- Can be connected with one S-B10AL(P) or one S-B10RP.

Layout Dimension