S-B15 Automatic 6H Seamer

S-B15 Automatic 6H Seamer

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

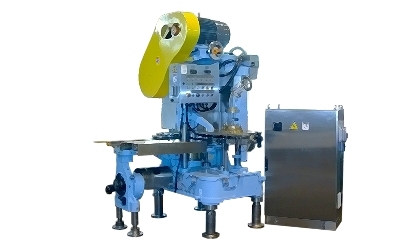

S-B15 (H) Automatic 6H Seamer is specially designed for round food can closing. Filled can is fed forward through a timing screw and a chain to enter seaming station equipped with 6 sets of seaming spindle. Turning lifter plate lift can up to meet with end . Two seaming rollers undertake seaming operation. Cam driven knock out pad release the seamed can from chuck and seamed can is carried out by a turret. End magazine has three sets of tiny separating knife. Seam quality meet international standard. Simple structure and multiple safety devices, easy for operation and maintenance.

coming soon

Specifications

| Machine Type | S-B15 |

|---|---|

| Range of Can Dia. | 202 - 401D |

| Range of Can Height | 48 - 180 mmH |

| Capacity Per Min. | Up to 400 Cans |

| Horse Power Required | 10HP x 1 |

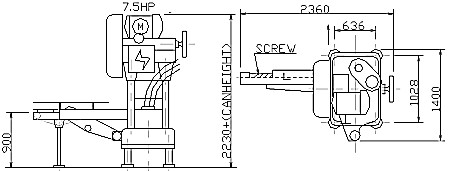

| Floor Space Overall Height | 1400L x 2360W x 2365H mm |

| Net Weight | 2500 kgs |

Features

- Automatic lubrication system provided for all moving parts except seaming heads & lifters.

- Proximity switch used for no can no cover system.

- Lid marker attached to the machine available.

- Variable pulley used for continuous speed adjustment.

- System flow equipment available.

- Invertor is available for variable running speed.

- Under cover gasing system is available on request for canning.

- Equipped with three end separating knives on end magazine.

- Equipped wth driven spin lifter plates.

Layout Dimension