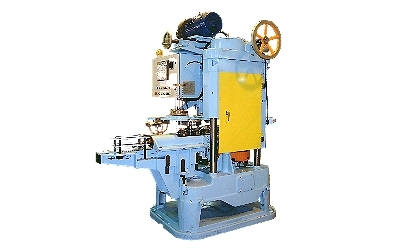

S-B15APH Automatic 6H Double Seamer

S-B15APH Automatic 6H Double Seamer

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

S-B15APH Automatic 6H Seamer is specially designed for round empty can closing. Flanged can is fed forward through a timing screw and a chain to enter seaming station equipped with 6 sets of seaming spindle. Turning lifter plate lift can up to meet with end . Two seaming rollers undertake seaming operation. Cam driven knock out pad release the seamed can from chuck and seamed can is carried out by a turret. End magazine has three sets of tiny separating knife. Seam quality meet international standard. Simple structure and multiple safety devices, easy for operation and maintenance.

coming soon

Specifications

| Machine Type | S-B15APH |

|---|---|

| Range of Can Dia. | 115D - 307D |

| Range of Can Height | 45 - 300 mmH |

| Capacity Per Min. | Up to 260 Cans |

| Horse Power Required | 7.5HP |

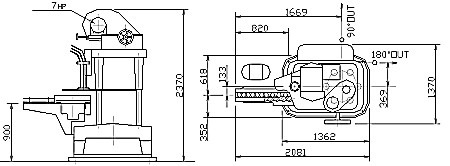

| Floor Space Overall Height | 2360 x 1400 x 2470 mm |

| Net Weight | 2850 kgs |

Features

- No can No cover system and low cover stacking detecting.

- Mounting with MIKI pulley for varible running speed control.

- Operational safety controls are built for long life.

- Can guide and Turret hard chromium plating.

- Feeding Table with Timing spiral and stopper for full line Auto control.

- B15AP and B15APH special for normal aerosol can.

- B15S special for small aerosol can.

- Equipped with three end separating knives on end magazine.

Layout Dimension