S-B18-2(M) Automatic Strip Feeder Machine

S-B18-2(M) Automatic Strip Feeder Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

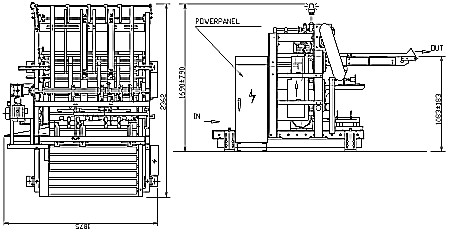

S-B18-2(M) Automatic Strip Feeder is to link with press for end stamping or can body drawing. Strip piled pallet is to be sent into lower roller table. Rollers on the table ,driven by a motor, turn and carry the pallet forward. Forks lift strip stack up and gradually lift up. Three suction pads suck strip up one by one and send it out. When strips are not enough, four small stoppers extrude out to temporarily support remnant strips. At the same time, forks immediately lower down to lift second stack up to replenish strips so as to feed strips continuously into press. With simple design and multiple safety devices, easy for maintenance and can size changeover.

coming soon

coming soon

Specifications

| Machine Type | S-B18-2 | S-B18-2M | S-B18-2L |

|---|---|---|---|

| Connecting Width M/C Type | S-B18GL | S-B18 / S-B9B | S-B18GLL |

| Strip Length | 760 - 1065mm | 760 - 1040mm | 760 - 1065mm |

| Strip Width | 115 - 300mm | 230 - 400mm | |

| Capacity Per Min. | 40 SPM | 40 - 25 SPM | |

| Horse Power Required | 1HP x 1 , 1/2HP x 3 | ||

| Compressor Air Required | 3 BAR x 20L/min. | ||

| Floor Space Overall Height | 2850 x 1870 x 1700 mm |

2850 x 1780 x 1700 mm |

3170 x 1890 x 1980 mm |

| Net Weight (approx.) | 1600 kgs | 1700 kgs | 1800 kgs |

Features

- Strips can be feeded with 180 turnover.

- With vacuum to pickup strips suitable for steel and aluminum plate.

- Completely synchronized with Press feeding.

- Multi-safety design for machine and personnel safety.

- Easy for can size changeover and adjust.

- Save operating labor to reduce cost.

- Can be connected with press model S-B9B,S-B18,S-B18G(5) or S-B18GL, S-B18GLL to save labor cost.

- A special design robot strip feeding cart is available on request for one S-B37SA and two or three S-B18-2(M) operation.

Layout Dimension