S-B23B Automatic Feeding Machine

S-B23B Automatic Feeding Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

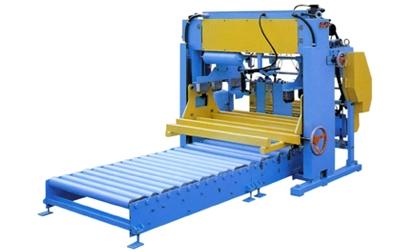

S-B23B Automatic Sheet Feeding Machine is designed for square tinplate or aluminium sheet feeding. Piled tinplate or aluminium sheet on pallet is fed into and is right positioned on the lower roller table. Roller table is lifted up via two chain drived by a hydraulic cylinder. Sheets are separated by several magnetic sets or air blowing system, then is sucked up by three sets of vacuum pads and sent out. Sucking force on the pads is created by vacuum generators. The machine can be linked and work with gang slitter or scroll shear. With simple design and multiple safety devices, easy for maintenance and operation.

coming soon

coming soon

Specifications

| Machine Type | S-B23B |

|---|---|

| Max. Tinplate Size | 1145 x 1145 mm |

| Min. Tinplate Size | 600 x 600 mm |

| Max. Tinplate Lifting Capacity | 2000kgs |

| Feeding Speed Per Min. | Up to 40 SPM |

| Compressed Air Required | 5kgs x 250L/min |

| Sheet Outlet Height | 882mm |

| Horse Power Required | 1HP x 1 , 1/2HP x 1 , 1/4HP x 1 |

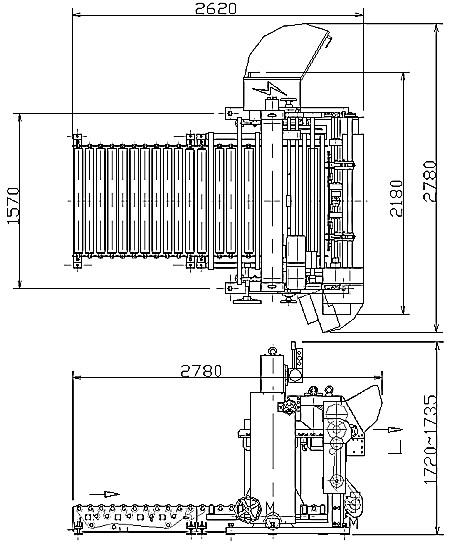

| Floor Space Overall Height | 2820 x 2120 x 1670 mm |

| Machine Net Weight (Approx) | 1270 kgs |

Features

- Very sturdy structure of machine, suitable for all tinplate of non-ferrous sheet feeding.

- Built with driving mechanism, easy connecting with any Slitter or scroll shear.

- Easy for maintenance and adjustment.

- Multi-safety design to insure machine and personnel safety.

- Roller table use drive reducer suitable for one operator serves multi feeders.

- Tinplate ( or aluminium ) sheet is carry up by three suction pads, three vacuum generators are equipped.

- Several magnet separators are equipped for tinplate sheet while air blowing separators for aluminium sheet.

Layout Dimension