S-B59 Automatic 4H Double Seamer

S-B59 Automatic 4H Double Seamer

- Product Info

- Product Sample

- Machine Video

- Machine Animation

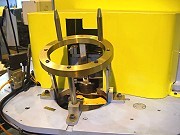

- Close View / Tooling

- Specification / Features

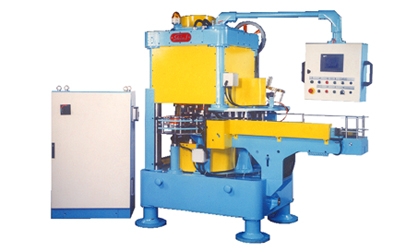

S-B59 Automatic 4H Double Seamer is an excellent seamer for medium production purpose. Equipped with four chucks spindles. Cans are carried through a timing screw and turret to enter seaming station while ends are separated by a separating knife then carried by an end turret so as to meet with cans. Gear driven spin lifter system lift cans up then a pair of seaming rollers, made of alloy steel or stainless steel, undertake seaming operation. Seaming quality meet international standard. Suitable for empty can making or canning factory. With multiple safety devices and centralized lubrication system, for safe operation and easy maintenance. Besides, simple structure design, easy for can size changeover.

Specifications

| Machine Type | S-B59 |

|---|---|

| Range of Can Dia. | 401 - 800D |

| Range of Can Height | 100 - 280 mmH |

| Capacity Per Min. | Up to 200 Cans |

| Horse Power Required | 7.5HP or 10HP if link filler |

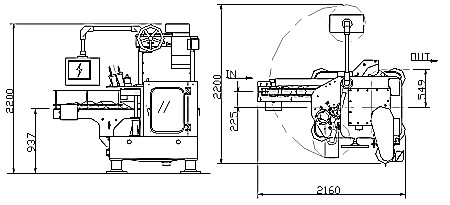

| Floor Space Overall Height | 2160L x 2200W x 2200H mm |

| Net Weight | 3500 kgs |

Features

- No can No cover system and low cover stacking detecting.

- Operational safety controls are built for long life.

- Can guide and Turrent with chromium plating or stainless steel material.

- Available choice of under cover gassing system for steam or N2.

- Easy for different can size changeover.

- Use human-machine interface (touchable monitor) control system and inverter for setup and variable speed control.

- Equipped wth gear driven spin lifter plates.

- Number of end separating knife can be one or three depending on end shape.

Layout Dimension