S-B65 Automatic 12H Double Seamer

S-B65 Automatic 12H Double Seamer

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

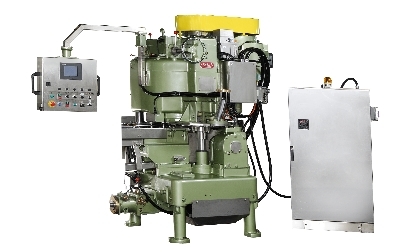

S-B65 Automatic 12H Seamer is specially designed for round empty or food can closing. Flanged (or filled ) can is fed forward through a timing screw and a chain to enter seaming station equipped with 12 sets of seaming spindle. Turning lifter plate lift can up to meet with end. Two seaming rollers undertake seaming operation. Cam driven knock out pad release the seamed can from chuck and seamed can is carried out by a turret. Seam quality meet international standard. Simple structure and multiple safety devices, easy for operation and maintenance.

coming soon

Specifications

| Machine Type | S-B65 |

|---|---|

| Range of Can Dia. | 200 - 301D |

| Range of Can Height | 30 - 200 mmH |

| Capacity Per Min. | Up to 1200 Cans |

| Horse Power Required | 20HP |

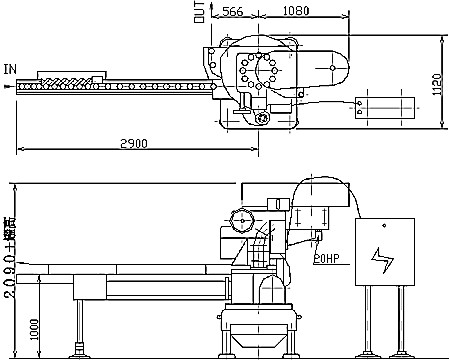

| Floor Space Overall Height | 3000L x 1300W x 2300H mm |

| Net Weight | 3600 kgs |

Features

- Automatic lubrication system provided for all important part except seaming rolls.

- Non-touch reject detector to keep cans from jam and damage.

- Can be equipped with steam flow device, as well as under cover gasing device.

- Can be connected with liquid filler.

- Adopt various emergency stop device.

- An inverter is used for smoothly & continuosly seaming speed change.

- Under cover gasing system is available on request for canning.

- Equipped wth driven spin lifter plates.

Layout Dimension