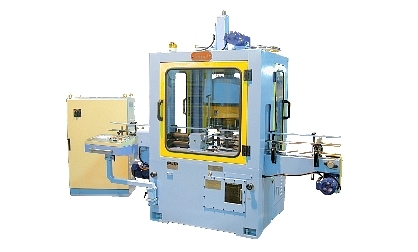

S-B74 Automatic Vertical Flanging Machine

S-B74 Automatic Vertical Flanging Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

S-B74 Automatic Vertical Flanging Machine with vertical design is easily linked and work together with automatic double seamer. Can cylinder is carried by a timing screw and a turret to let swing flanging die to form flange. Then, flanged can body is carried out by a turret. Swing flanging works by two symmetric swing discs to slightly and evenly squeeze can fringe. With recycleable centralized lubricating system and multiple safety devices, easy for maintenance and can size changeover.

coming soon

Specifications

| Machine Type | S-B74 | ||

|---|---|---|---|

| Model Type | 4H | 8H | 12H |

| Range of Can Dia. | 200 - 401D | 200 - 301D | |

| Range of Can Height | 70 - 210 mmH | 80 - 200 mmH | 90 - 200 mmH |

| Capacity Per Min. | Up to 400 Cans | Up to 800 Cans | Up to 1200 Cans |

| Horse Power Required | 3HP | 5HP | |

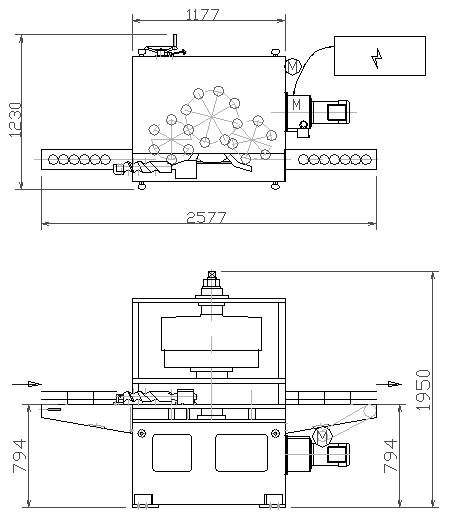

| Floor Space Overall Height | 2577L x 1190H x 1950W mm | ||

| Net Weight | 2500 kgs | 3000 kgs | 3500 kgs |

Features

- Vertical design easy to connect with auto double seamer.

- Recycleable center control lubricating system.

- Use human-machine interface (touchable monitor) control system and inverter for setup and variable speed control.

- Can guide and Turrets with hard chromium plating or Nylon material.

- Full Automatic Control system for canmaking line requirement.

- Multi-safety design for machine and personnel safety.

- Swing flanging works by two symmetric swing discs while spin flanging works by several gear driven rollers.

Layout Dimension