S-B9B Automatic Strip Feed Press Machine

S-B9B Automatic Strip Feed Press Machine

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

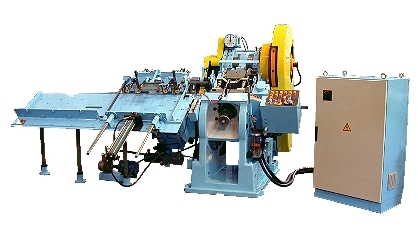

S-B9B Automatic Strip Feed Press is built for can end or battery jacket stamping. Piled strips are lifted by a set of hydraulic cylinders then suck pads send strip one by one to strip feeding station. (also can link with Automatic Strip Feeder S-B18-2M). Reciprocating feeding bar at feeding station push strip into punch tooling. Formed can end (or battery jacket) is ejected out via. an end kicker(or air blowing) to rear while strip scrap is ejected out by a pressing roller to side. Punch tooling is made of alloy steel; hence, sturdy for long life. An automatic lubrication pump and multiple safety devices are equipped for easy maintenance and safe operation.

coming soon

Specifications

| Machine Type | S-B9B | |

|---|---|---|

| Range of End Dia. | 200 - 714D | Irregular ends |

| Strokes Per Min. | 200 - 404D Up to 200 EPM 404 - 603D Up to 160 EPM 603 - 714D Up to 120 EPM |

Up to 120 EPM |

| Horse Power Required | 3HP, 2HP, 1HP, 1/4HP EA. | |

| Range of Strip Length | 510 - 915mm | |

| Range of Strip Width | 64 - 220mm | |

| Max. Die Height | 250mm | |

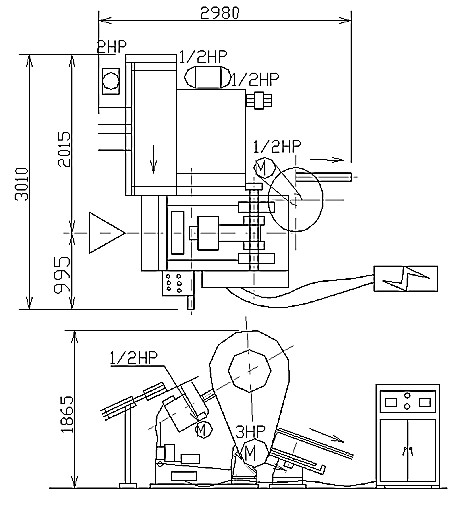

| Floor Space Overall Height | 3050 x 2980 x 1865 mm | |

| Net Weight (approx.) | 4800 kgs | |

Features

- Strips lifting by hydraulic cylinder and use proximity switch for strips height control.

- With duplex switch for machine starting, safe and reliable

- With Air Clutch for power transmission, effective but low maintenance.

- Multi-safety design for machine and personnel safety.

- Easy for can size changeover and adjust.

- Can be connected with automatic strip feeder model S-B18-2M to save labor cost.

- Formed ends are ejected by air blowing or mechanical kicker.

- Double sheet detector is equipped for safe strip feeding.

- Battery jacket punch is possible. Coil feeding system is introduced for this purpose.

Layout Dimension