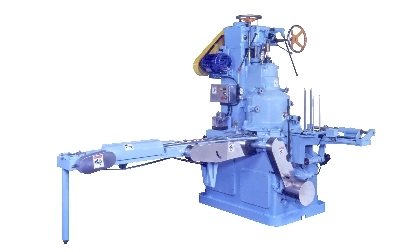

S-C25A Automatic Irregular Can Vacuum Seamer

S-C25A Automatic Irregular Can Vacuum Seamer

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

S-C25A Automatic Irregular Can Vacuum Seamer is specially designed for irregular can closing under vacuum . Filled can is fed forward through a timing screw and a chain to enter a pocket of vacuum turret, with eight pockets, in vacuum seaming station then meet with end. Lifter plate lift can up into vacuum chamber. Four seaming rollers undertake seaming operation. A concise seaming head with adjustable chuck set, make seaming quality meet international standard. Each seaming arm is controlled by an individual seaming cam and a copy disc is to guide rollers turn accordingly. Simple structure and multiple safety devices, easy for operation and maintenance.

coming soon

Specifications

| Machine Type | S-C25A |

|---|---|

| Range of Can Dia. | 45 - 100mm length, width |

| Range of Can Height | 20 - 100 mm |

| Maximun can diagonal | Up to 130 mm |

| No. of pocket on vacuum turret | 8 |

| Capacity Per Min. | Up to 60 cpm, depending on can shape, size |

| Main Motor | 3HP x 1 |

| Vacuum pump | 7.5HP x 1 |

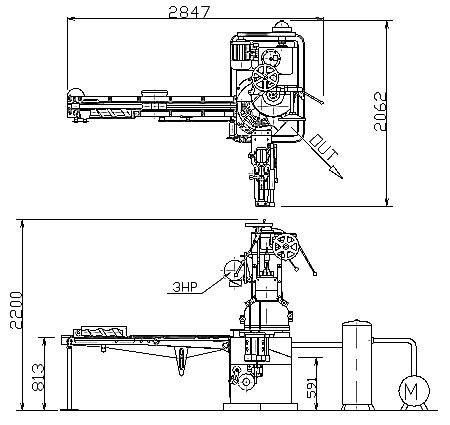

| Floor Space Overall Height | 2847L x 2062W x 2200H mm |

| Net Weight (approx) | 2200 kgs |

Features

- Seaming rolls movement is cam operated, hence makes seam seven perfect.

- Easy accessibility for maintenance.

- Simple mechanism and easy to operate.

- Wild range for different can sizes shapes.

- Special design for irregular filled can seaming.

- With mechanical knock-out pad, driven by a cam.

- Seaming chuck set is equipped with tiny twist adjustment device for better seam quality.

- One of the four seaming can function as curling roller for uncurled or bad curled lid.

- All parts contact with can/lid are made of stainless steel or bronze.

Layout Dimension