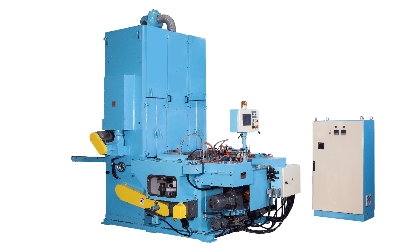

S-D31RP Automatic Irregular F.O.E Repair-Drying Machine (Two stations)

S-D31RP Automatic Irregular F.O.E Repair-Drying Machine (Two stations)

- Product Info

- Product Sample

- Machine Video

- Machine Animation

- Close View / Tooling

- Specification / Features

S-D31RP Automatic Irregular F.O.E. Repairing and Drying Machine , equipped with twin lining stations and twin drying ovens , is designed for non-round full open tin end scoring line lacquer repairing to avoid rust. Curled end is separated by a pair of separating knives on the end magazine; then, end is smoothly fed forward via two end pushing bars sliding on liner bearings. End is lifted up by a lower chuck to actuate NORDSON spraying gun, gun move forward-backward based on a cam contour to match the lower chuck turning so as to evenly spray lacquer on the scoring line. Repaired ends are pushed into oven by end feeding bars and carried up and down by two transfer screws inside the drying oven. Dried ends drop out at the oven bottom. Heating air is created and recycled through electric heaters and blowers. Simple structure and multiple safety devices, easy for operation and maintenance.

Specifications

| Machine Type | S-D31RP |

|---|---|

| Range of Can Dimensions | 59 x 70 - 110 x 165 mm |

| Capacity Per Min. | Up to 120 EPM |

| Horse Power Required | 2HP x 2 |

| Floor Space Overall Height | 4180L x 2340W x 3315H mm |

| Net Weight | 4500 kgs |

Features

- Swing stopper equipped at end magazine to avoid scratch on ends.

- End pushing bars move along linear bearing , reliable and sturdy.

- With NORDSON spraying guns, seal compound spray is even and compound quantity adjustment is easy.

- Automatic temperature controller is provided to adjust and keep the temperature in oven.

- Use human-machine interface (touchable screen) control system and inverter for set up and variable speed control.

- End guide and transfer screws are hard chromium plated.

Layout Dimension