S-M446 Automatic Irregular Can Double Seamer

S-M446 Automatic Irregular Can Double Seamer

- Product Info

- Product Sample

- Machine Video

- Machine Animation

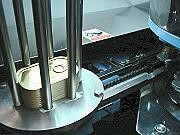

- Close View / Tooling

- Specification / Features

S-M446 Automatic Irregular Can Seamer with Clincher is specially designed for irregular can closing. Filled can is fed forward through a timing screw and a turret to meet with end. Clinching chuck and two clinching rollers push food down and clip end and can body together. Then, clinched can is carried by a turret and chain to enter seaming station. Lifter plate lift can up. Four seaming rollers undertake seaming operation. A concise seaming head with adjustable chuck set, make seaming quality meet international standard. Each seaming arm is controlled by an individual seaming cam and a copy disc is to guide rollers turn accordingly. Simple structure and multiple safety devices, easy for operation and maintenance.

Specifications

| Machine Type | S-M446 |

|---|---|

| Range of Can Dimension | 45 - 100mm Length, Width |

| Range of Can Height | 18 - 275mm |

| Maximun can Diagonal | Up to 160 mm |

| Capacity Per Min. | Up to 100 cpm |

| Horse Power Required | 3HP x 1 |

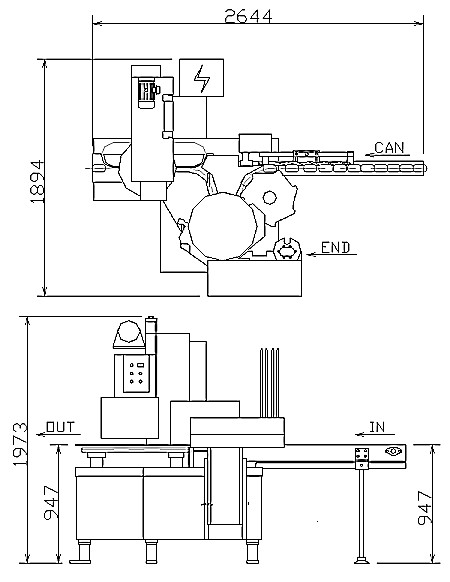

| Floor Space Overall Height | 1940 x 2600 x 2150 mm |

| Net Weight | 2050 kgs |

Features

- Very sturdy structure of machine, suitable for irregular can seaming.

- With rotary clincher for food product push down and clinch each cover to its can.

- The cover marker for maximun of triple raw and seven characters (Cover marker is optional).

- Easy for can size changeover and adjustment.

- All parts contact with the can body or lid made of stainless steel, easy for cleaningadn maintenance.

- With electronic No can No cover(NCNC) device.

- All parts contact with can/lid are made of stainless steel or bronze.

- Seaming chuck set is equipped with tiny twist adjustment device for better seam quality.

- One of the four seaming can function as curling roller for uncurled or bad curled lid.

Layout Dimension